Granulator Blade Sharpening Service

Fernite offers the UK’s #1 granulator blade sharpening service.

Sharpening Service

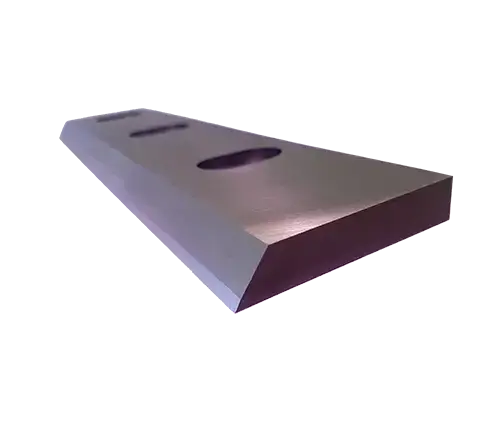

We understand that achieving the perfect cutting edge is crucial when sharpening a granulator blade.

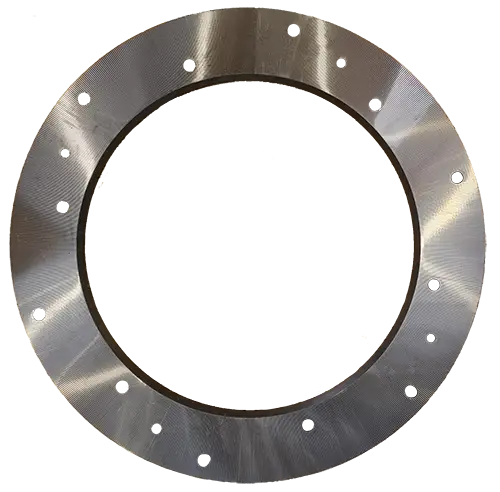

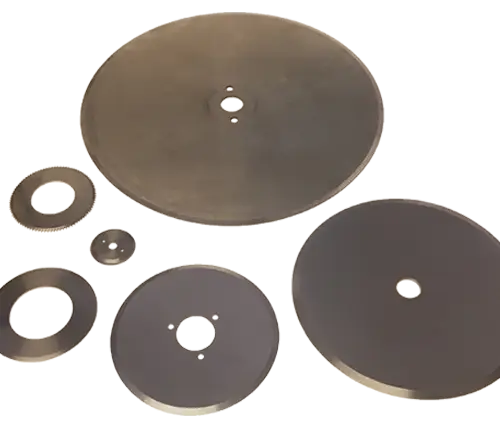

Fernite operates the most comprehensive granulator blade sharpening services in the UK, for virtually every make and model.

When granulator blades become dull, they tend to smudge and rip plastic rather than cut it cleanly. This dullness also leads to increased vibration and waste. To ensure optimal cutting results and reduce wear on the granulator, it’s essential to maintain blades in sharp condition. Regular sharpening can extend the life of your blades, reduce machine downtime and make significant cost savings compared to buying new granulator blades.

Neglecting blade maintenance can result in poor-quality granulate with excessive dust content in both the material and the plant environment. However, regular blade changes and proper settings can ensure excellent results.

You can easily monitor the quality of the regrind yourself. First, collect the regrind material and check its consistency. Are the pieces roughly the same size? How do they compare to the size of the pellets you’re using? Next, drop the material back into the container and see how much dust and fines remain on your hand. A well-maintained and operated granulator should leave minimal residue.

Expert Team and Comprehensive Service

Our expert team meticulously sharpens every granulator blade, restoring a sharp edge essential for optimal performance.

Our granulator blade sharpening service, provided from ISO9001 accredited manufacturing sites, efficiently serves our customers nationwide. As the UK’s leading blade sharpening service with a 7-day turnaround, we’re ready and able to help you wherever you’re located.

Our technical department is available to help and advise on any issues you may encounter. When you need consistency and quality, our reputation and technical expertise ensure a superior regrind every time.

When to Consider Replacement

If a blade is severely chipped or has been re-ground to more than 1mm below its original thickness, it may not fit properly. In these cases, we may recommend a new set of replacement granulator blades.

Fernite supply new blades for all brands of granulator machines, plus of course, if it has a cutting edge, we’re confident that we can sharpen it.

Get in touch to find out more, or book your collection today.